Careers

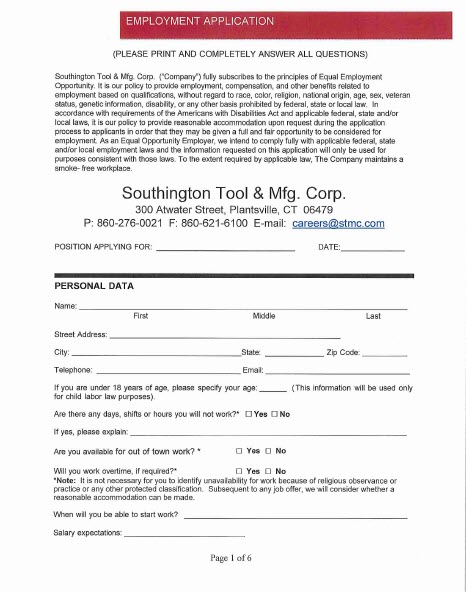

Southington Tool & Manufacturing is always looking for highly skilled individuals to join our team. If you possess the skills listed and would like to work in a world-class company, please submit your resume or download a written application below.

Quality Assurance Inspector/Technician

Southington Tool is looking for an experienced Technician needed to support various Quality Control activities.

Class A Toolmaker

STMC is currently accepting applications and resumes for a Class A Toolmaker with progressive die building and debug experience.

Journeyman Tool & Die Maker

Southington Tool is looking for an experienced Tool & Die Maker for die making, troubleshooting and die maintenance.